In today's complex logistics landscape, knowing the exact location of every asset isn't just convenient—it's mission-critical. With shipping containers stacked across acres of yard space, trailers constantly moving between loading bays, and railcars transferring between tracks, the inability to quickly locate specific assets creates costly bottlenecks that ripple throughout the supply chain. Real-time location systems (RTLS) have emerged as the solution to this challenge, but not all approaches deliver equal results in the demanding environments of ports, rail yards, and truck terminals.

Why Real-Time Location Systems Are Essential in Today's Logistics Operations

The growing complexity of global supply chains has transformed what was once a straightforward operation into a high-stakes coordination challenge. Logistics operations lose thousands of labor hours annually searching for misplaced assets, while yard congestion leads to trucks exceeding their targeted dwell time—directly impacting downstream delivery schedules and customer satisfaction.

Real-time location systems transform operational visibility by providing instant answers to the critical question: "Where is asset X right now?" This seemingly simple capability dramatically impacts decision-making across the operation:

- Yard managers can rapidly identify available storage locations

- Dispatchers can locate specific containers or trailers without physical searches

- Operations teams can track dwell time violations before they impact schedules

- Planners can optimize yard layouts based on actual movement patterns

The High Cost of Visibility Gaps

The absence of reliable real-time location data creates cascading problems across logistics operations:

- Asset underutilization: Equipment sitting idle because its availability status is unknown

- Extended dwell times: Assets remaining in facilities longer than necessary due to inefficient retrieval

- Safety incidents: Congested yards creating hazardous conditions for workers and equipment

- Capacity constraints: Inefficient space utilization limiting throughput potential

Trucks wait in line. Credit: The Wall Street Journal

Multi-Camera Tracking: Transforming Logistics Yards into Smart, Visible Operations

Multi-camera tracking represents a fundamentally different approach to real-time location systems, addressing the inherent limitations of traditional tag-based solutions while delivering comprehensive visibility without the operational burden of hardware maintenance.

How it works: Multi-camera tracking leverages networks of standard surveillance cameras combined with advanced computer vision and AI algorithms to detect, classify, and track objects throughout the facility. The system continuously monitors all assets in camera view, maintaining their identity as they move between different camera perspectives.

Unlike single-camera surveillance systems, multi-camera tracking solutions maintain consistent object identity across the entire facility by using sophisticated spatial mapping and trajectory analysis. The technology effectively creates a comprehensive digital twin of the yard, showing the real-time position of every tracked asset.

The technological foundation includes:

- Computer vision: Advanced object detection and classification algorithms that can distinguish between different asset types (containers, trailers, trucks, railcars)

- AI and machine learning: Systems that improve over time, learning to recognize objects in various conditions and environments

- Real-time processing: Edge computing that enables immediate analysis of video feeds without latency

- System integration: APIs and connectors that feed location data into existing yard management systems

- Scalable architecture: Distributed processing capability that expands to cover yards of any size

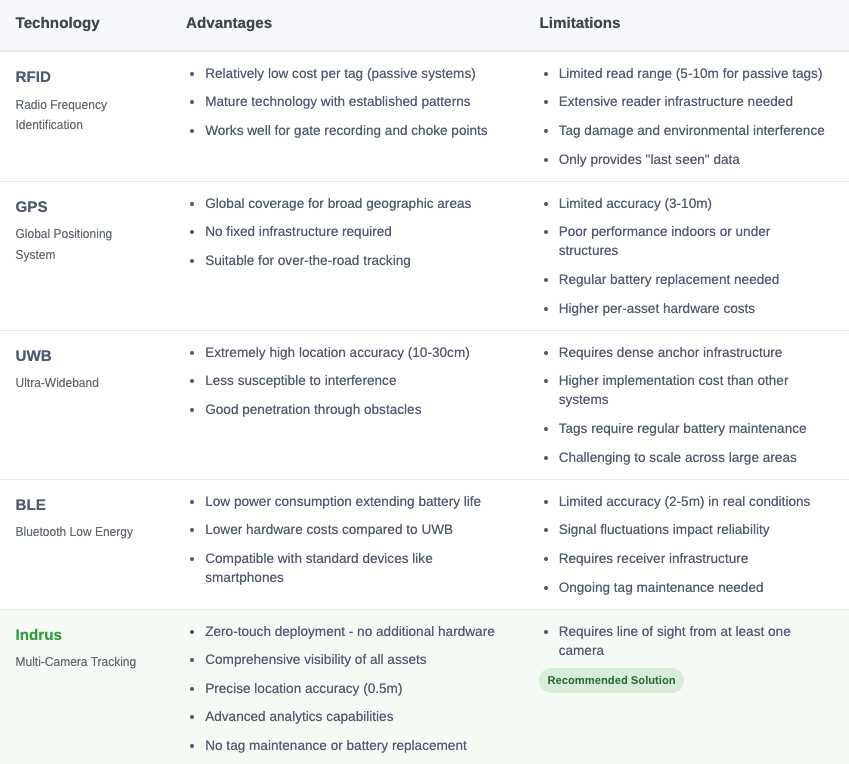

Comparing Real-Time Location System Technologies for Logistics Environments

The market offers several approaches to real-time location tracking, each with distinct advantages and limitations for logistics applications. Understanding these differences is crucial for selecting the right solution for your specific operational needs.

Real-time Locations System Comparison Table

Real-Time Location System Simplified Comparison Breakdown

Key Advantages of Multi-Camera Tracking Over Traditional RTLS

Multi-camera tracking solutions offer several significant advantages that make them particularly well-suited for the challenging environments of logistics yards:

- Zero-touch deployment: No tags, beacons, or hardware installation on the assets themselves means no operational disruption during implementation and no ongoing maintenance of thousands of individual tracking devices.

- Comprehensive visibility: The system tracks every asset in the facility, not just those with functioning tags, ensuring nothing falls through the cracks.

- Precise location accuracy: Modern systems provide location data with 1-3 meter accuracy—sufficient for practical logistics operations without the infrastructure complexity of UWB systems.

- Reduced infrastructure maintenance: Fixed camera systems require significantly less ongoing maintenance than distributed tag readers or anchors throughout a facility.

- Advanced analytics capabilities: Beyond simple location data, camera systems can provide rich contextual information about asset condition, yard activity patterns, and operational anomalies.

- Long-term cost advantage: While initial implementation may be comparable to other technologies, the elimination of recurring tag costs and maintenance creates substantial TCO advantages over 3-5 year timeframes.

The Future of Logistics Operations: Visibility as the Foundation

As logistics operations continue to face increasing pressure for efficiency, throughput, and responsiveness, real-time location systems will transition from competitive advantage to operational necessity. The most successful operations will be those that implement solutions offering comprehensive visibility without adding operational complexity.

Multi-camera tracking represents not just an alternative to traditional real-time location systems, but a fundamental evolution in approach—eliminating the complexity of tag-based solutions while expanding visibility across the entire operation. For logistics yards facing challenges with asset visibility, operational efficiency, and space utilization, this technology offers a transformative capability that directly impacts bottom-line performance.

When evaluating real-time location systems for your logistics operation, consider not just the initial implementation costs, but the ongoing operational impact. Will the solution eliminate manual searches? Does it require maintenance of thousands of individual tracking devices? Can it scale with your operation and integrate with your existing systems? The answers to these questions will guide you toward the solution that delivers sustainable value.

The future of efficient logistics operations isn't just about moving assets faster—it's about knowing precisely where they are at every moment. With multi-camera tracking technology, that future is available today.